SK-620 two-sided self-adhesive labeling machine suitable for flat bottle,irregular-shape bottles,round bottle, square bottle products in daily chemical,household chemical,pharmaceutical,food and other light industry.It can do single or double sided stickers standard labeling, with optional ribbon printer and inkjet printer.It can print production lot number, production date and other information at the same time when labeling to achieve the integration of labeling and ink-jet printing, reduce packaging processes, improve production efficiency.This adapts to adhesive labeling machine, self-adhesive film, electronic regulatory code,bar code,two-dimensional code labels,transparent labels.The equipment is high stability, good labeling effect, no bubbles, no wrinkles, high labeling accuracy.

labor put products (inline with unscrambling turntable ->Products are automatically corrected and delivered separately->Product testing->Product labeling->Collect the labeled products(go to the next step)->Take away the product

Put different packaging objects into the labeler conveyor belt then driven into the bottle sub-area, after the correct machinery,pass into labeling area by holding mechanism . After entering the labeling area,the optical fiber detect the bottle, the photoelectric signal is transmitted to PLC, processed by the PLC after the output signal is transmitted to the stepper motor.The stepper motor will output label, through the rolling mechanism will be affixed to the label objects. The labeled object will into the next process or container by the labeling machine conveyor belt.

High compatibility,the same device can achieve a variety of products:single and double side and adjacent rectangular surface labeling (such as: flat bottle, round bottle, square bottle, special-shaped bottle, etc.),optional round bottle positioning mechanism, round bottle roll rolling institutions, three sides of covering label mechanism.

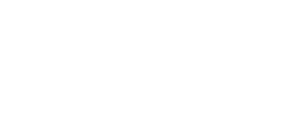

Flexible application,simple operation,can stand-alone production and production in the assembly line,use double-sided rigid plastic synchronous guide chain automatically guarantees the bottle to the center, which greatly reduces the worker's work or assembly line difficulty in docking. Equipped with automatic bottle-dispensing mechanism is arranged to automatically separate the distance before the product enters the guide mechanism to ensure the subsequent guide bottle,delivery and labeling stability.

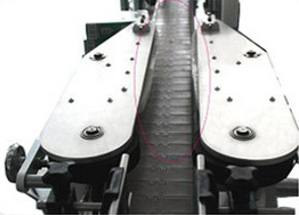

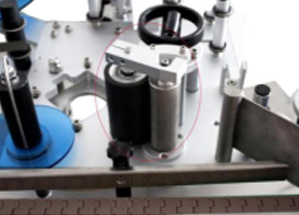

Configure double covering-label mechanism,first time covering-label to ensure labeling accuracy, secondary extrusion covering-label effectively eliminate bubbles and ensure the tag close tightly at the head and tail;

The use of a new type of spring-top pressure mechanism to ensure smooth product delivery, and effectively eliminate the bottle height itself error;

Accurate labeling high stability, use of PLC+subdivision stepper motor driven to output label, accurate delivery label; adopt cam-type brake mechanism, uniform tension to ensure tape taut and reduce the label pull off also ensure label detection accuracy; Band bypass correction device to prevent the label around the offset to ensure the accuracy of label output;

Powerful function and colorful touch screen control, Chinese and English optional interface, convenient and intuitive, powerful data memory function, can store 50 sets of labeling parameters, with production counting function, power saving function; production number setting prompt function, parameter setting protection function, convenient production management, different products labeling switching a key to achieve, without repeated testing, simple and quick; has a complete fault tips and help functions;the number of production settings prompt function, parameter setting protection , Convenient production management, different products labeled switch to achieve a key, without repeated testing, simple and quick; and has a complete fault tips and help functions;

High stability, testing label and object sensors are imported brands, high detection sensitivity, stable performance, durability; solid and durable machine stand and the various parts are adopted standard modular design with complete interchangeability, 24 Hours running to ensure safety and stability.

Safety and health, chassis use stainless steel SUS304 material and T6 aluminum alloy, never rust, in line with the GMP fine manufacturing standards;

Voltage specifications | AC220V 50/60HZ |

Power consumption | 2500W |

Labeling speed | 120-250 bottles/min (adjustable speed, depending on the size of the object and label length) |

Labeling accuracy | +1mm (depending on product characteristics, like hardness ) |

Bottle diameter | 25-120mm |

Object range | Height 40-400mm (can be customized ) |

Label specifications | height 10-150mm length 10-300mm(special specifications can be customized) |

Paper roll diameter | inner diameter:Φ76mm outer diameter:Φ350 (max) |

Weight | 280KGS |

Packing size | 2800X1400X1400mm |

Conveyor width | can be customized according to customers' sample bottle |

NO. | Part Name Rating | Quantity | Brand |

1 | Labeling servo motor | 1 | Japan Panasonic |

2 | Labeling motor drivers | 1 | |

3 | Conveyor motor | 1 | China |

4 | Conveyor motor gear box | 1 | |

5 | bottle dividing motor | 1 | China VTV |

6 | bottle dividing motor gear box | 1 | |

7 | Correction motor | 1 | |

8 | Correction motor gear box | 1 | |

9 | Press label motor | 2 | |

10 | Press label motor gear box | 2 | |

11 | Label photoelectric | 2 | Japan Keyence |

12 | Label detection photoelectric | 2 | |

13 | PLC | 1 | German Siemens |

14 | HMI | 1 | |

15 | frequency converter | 1 | |

16 | conveyor | 1 | China |

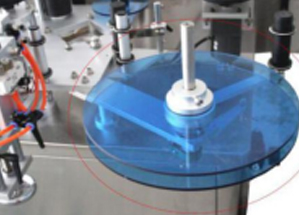

Bottle dividing correction device:accurate differential bottle dispensing mechanism, bottle diving accuracy up to ± 5mm, ni need to change additional parts when replace different specifications’ bottle cost savings, easy to adjust.

Labeling Power Agency: Super wear-resistant calibration device use a special rubber material, durable and wear-resistant. In RXL-DS equipment instal the label device, not only can meet double-sided labeling, but also can meet round bottle labeling.

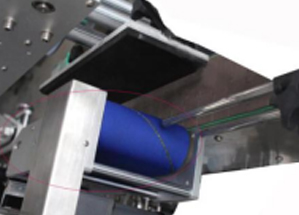

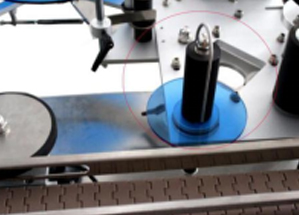

Top label device: motor control, same speed with conveyor track, to control bottle is kept upright to prevent falling bottles.

label roller device: beautiful, dustproof, with the label for easy and convenient.

Pulling label mechanism: motor control and conveyor synchronization, output label.

Collecting label institutions: motor control and conveyor belt, pulling label synchronization, collecting end paper labels.

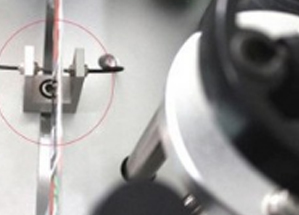

Peeling institutions: can adjust the position of the label to be removed from, rapid fine-tuning the location of peel label and feed label,convenient to change label.

Photoelectric Detection:control the bottle and the label one-to-one correspondence, no bottle no label output, not repeat the label.

PLC HMI touch screen: use imported touch-screen HMI, all is in English display, as long as follow the instructions on the display operation, without any experience, you can easily on-line, greatly reducing staff training time; can be arbitrarily set production speed, can automatically adjust the production speed, with the speed of any production line for the most efficient production operation.

Alarm system:If there is any abnormal fault: If there is a label running out, broken tape,ribbon out,count setting to mechanical abnormalities and other conditions,it will automatically shut down and give an alarm.

Transport chain board: imported brands,easy to clean,durable.

Chassis: Stainless steel SUS304 material and T6 aluminum alloy, never rust, in line with GMP standards.

Foundation Cream

Make Up Remover

Nail Varnish

Nail Varnish Remover

Shampoo

Conditioner

Liquid Soap

Bath & Shower Gel

Roll On Deodorant

Stick Deodorant

Toothpaste

Fragrance

Perfume

Nail Varnish

Nail Varnish Remover

Shampoo

Conditioner

Hair Gel

Hair Wax

Hair Styling Products

Hair Dye

Tel: 0086-13616137022

Fax: 0086-519-82797687

Email: sales@jpacks.com

Add: No.3 Building 1, Jinbotong, Yangang East Road, Jintan, Changzhou, Jiangsu, China