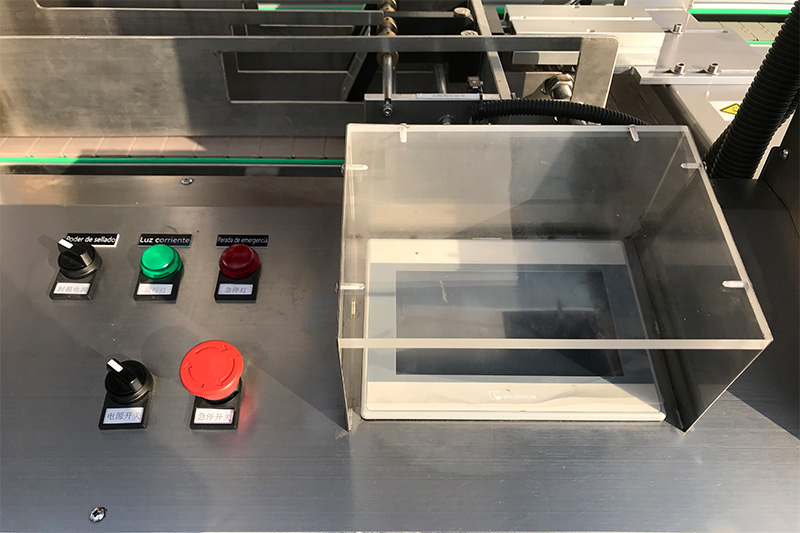

Automatic positioning of high-precision rod dispensing device, accurate bottle spacing control, easy to pour the bottle.

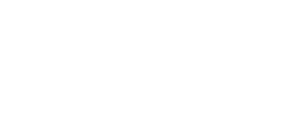

Using touch screen operation, to achieve man-machine dialogue, convenient and intuitive, simple and clear.

Advanced and simple automatic feeding device, effectively avoid the inertia of the conveyor belt, keep the bottle and carton speed and stable operation.

The machine automatically detects the running status. If the machine does not have the packing signal for a long time, it will automatically enter the semi-sleep state, reduce the running speed, reduce the mechanical loss and reduce the energy consumption, and prolong the service life of the machine.

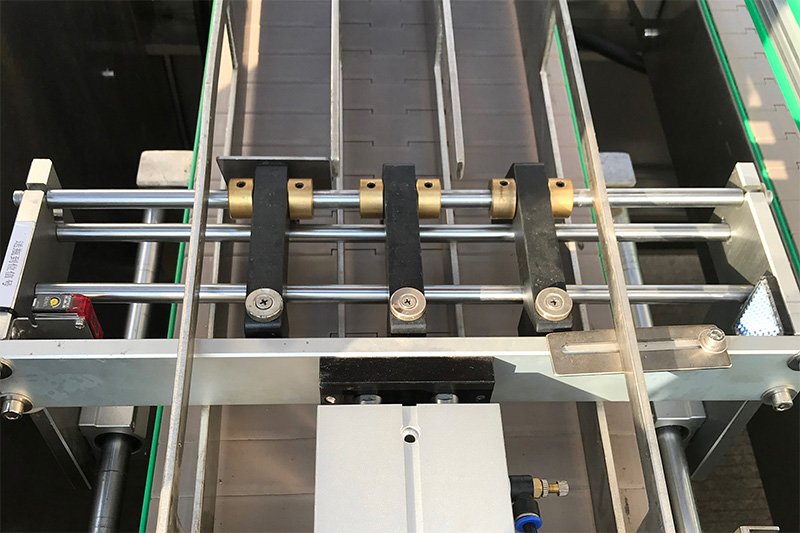

The main electrical control components (touch screen, PLC, inverter, motor, photoelectric switch, etc.) use internationally renowned brands, industrial control industry's top products, so that the machine can be fundamentally guaranteed in quality.

JZX series packing machine configuration and parameters (Annex 2)

The main unit is as large as: L1450×W1020×H2300mm

This model has a 4 meter conveyor belt.

Packing machine weight: about 800KG.

Applicable bottle shape capacity: 350ML-2.0L.

Applicable bottle type: round.

The power supply of the cartoning machine: 220V.

Packing machine speed: normal operating speed 800 boxes / hour.

Packing machine power consumption: 4KW.

The bottle head needs to be replaced when the bottle shape is different.

The conveyor belt is located in the section where the cartoning machine is located, and its power is controlled by the cartoner.

Equipment air source pressure: 0.3-0.5Mpa, cylinder working pressure is 0.3Mpa, and head working pressure is 0.2-0.3Mpa.

The original reciprocating and cyclic gripping head is fast and accurate.

Replaceable bottle grab tips, which are easier and less expensive to replace.

Touch screen control box: The operation is more personalized.

PLC: Mitsubishi

Servo motor: Panasonic

Servo drive: Panasonic

Inverter : Schneider

Sensor: German Sick

HMI: Kinco

Pneumatic components: Airtac

Foundation Cream

Make Up Remover

Nail Varnish

Nail Varnish Remover

Shampoo

Conditioner

Liquid Soap

Bath & Shower Gel

Roll On Deodorant

Stick Deodorant

Toothpaste

Fragrance

Perfume

Nail Varnish

Nail Varnish Remover

Shampoo

Conditioner

Hair Gel

Hair Wax

Hair Styling Products

Hair Dye

Tel: 0086-13616137022

Fax: 0086-519-82797687

Email: sales@jpacks.com

Add: No.3 Building 1, Jinbotong, Yangang East Road, Jintan, Changzhou, Jiangsu, China