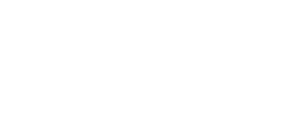

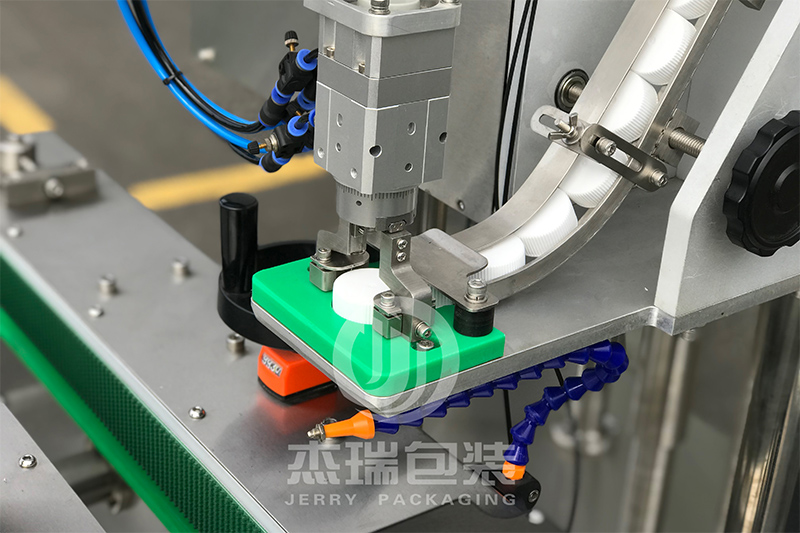

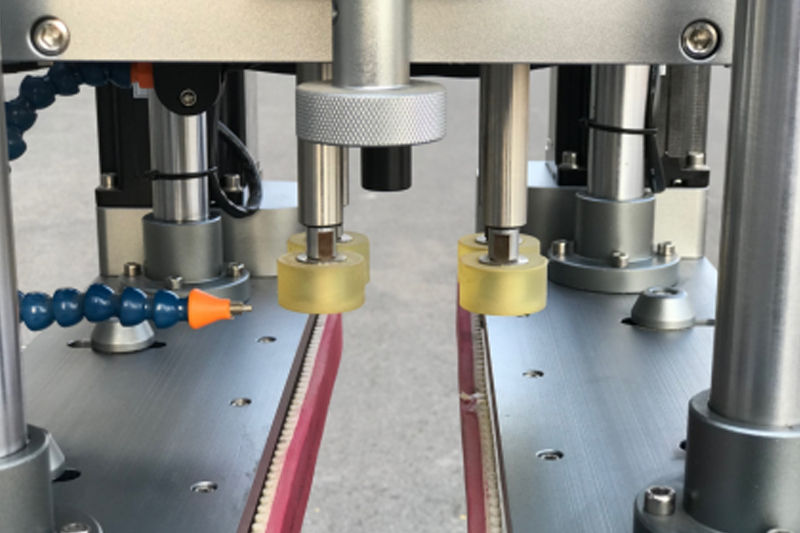

JPPU-40 serials are cap chuck capping machine, the pick & place device which picks up the cap from the chute and places it on the container, then capping chuck tightens.

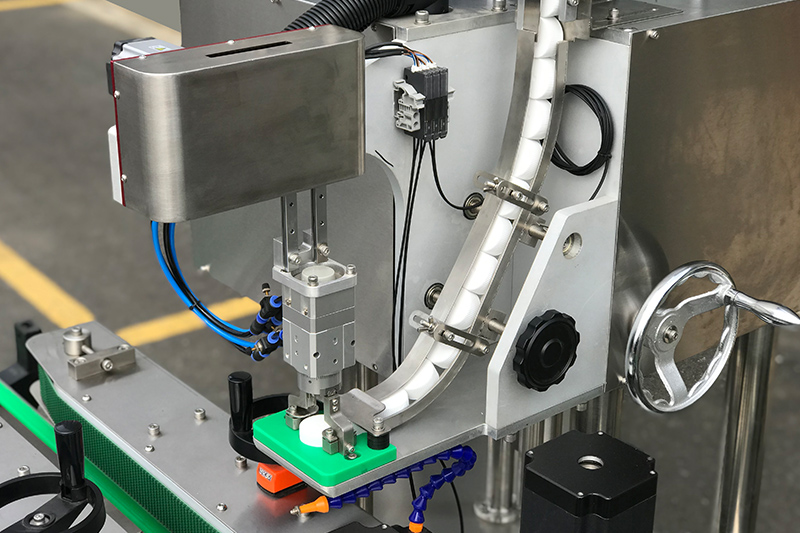

The linear capping machine has high capping speed, high pass rate and easy operation. Applicable to different bottle-shaped screw caps in food, pharmaceutical, daily chemical, pesticide, cosmetics and other industries. Four speed-regulating motors are used for cap feeding, bottle clamping, conveying and capping. The machine has a high degree of automation, good stability, and easy adjustment. No spare parts are required when changing the bottle shape or cap, and it can be done by adjusting.

Heavy duty stainless steel frame. Explosion-proof electric cabinet.

PLC controlled with touch screen panel, easy access to all settings.

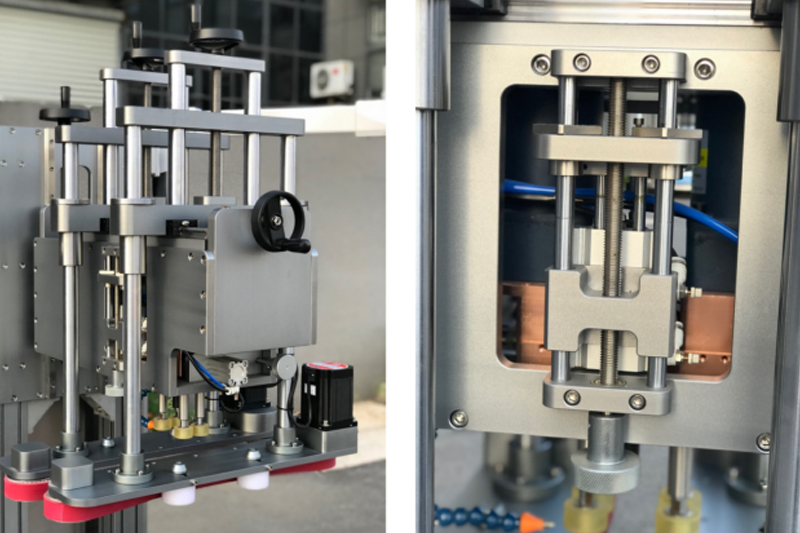

Pick & Place device is driven by servo motor with electrical cylinder.

Capping torque is set on the control panel.

Cap sorter unscrambles bulk caps and supplies to the cap chute for fully automatic application. (Vibration or Waterfall)

The vibratory cap sorter unscrambles bulk caps and supplies to the cap chute for fully automatic application.

Fast and easy capping head changeover into another cap type.

20 products can be stored in memory for recall.

Bottle height: 120mm-350mm

Bottle width (diameter): 50mm-150mm

Capacity: ~ 40 BPM.

Hold the rotating cylinder, take and place the cap or plug, and realize the function of pre screwing the cap.

Servo motor drives high-precision PPU cam manipulator. Fast speed and high repetition accuracy.

Adjust the hand wheel according to the height and width of the bottle. The servo motor drives the bottle clamping mechanism on both sides to realize fast start and stop.

Centrifugal Cap Sorting Bowl is also a great solution for high speed sorting and noise reduction for both flat, non-flat and specialty caps.Centrifugal Cap Sorting Bowl is also a great solution for high speed sorting and noise reduction for both flat, non-flat and specialty caps.

PLC: Japan Mitsubishi

HMI: China Kinco

Servo: Japan Panasonic

Photoelectric sensor: SICK

Low-voltage electrical appliances: Schneider, France

Photoelectric Sensors:Optex/Sick

Electrically controlled movement, strong stability; equipped with positioning device, standard screw cap, easy to operate; Wide range of lock caps, can lock bottle caps of different shapes and specifications; Solve the nozzle, pump head, spray pump, hand button spray head screw cap Difficult problems; The speed of the lock cap is adjustable, and the tightness can be adjusted according to different bottle caps.

Foundation Cream

Make Up Remover

Nail Varnish

Nail Varnish Remover

Shampoo

Conditioner

Liquid Soap

Bath & Shower Gel

Roll On Deodorant

Stick Deodorant

Toothpaste

Fragrance

Perfume

Nail Varnish

Nail Varnish Remover

Shampoo

Conditioner

Hair Gel

Hair Wax

Hair Styling Products

Hair Dye

Tel: 0086-13616137022

Fax: 0086-519-82797687

Email: sales@jpacks.com

Add: No.3 Building 1, Jinbotong, Yangang East Road, Jintan, Changzhou, Jiangsu, China