JLP-2000 automatic bottle unscramble machine is used to sort out disordered polyester or PET bottles. Scattered and unregulated bottles are sent from the elevator to the bottle storage ring of the unscramble machine. By the force of the fan, the bottle enters the bottle compartment Positioning Through the function of the bottle turning device, the bottles are arranged so that the mouth of the bottle stands upright, and the output is sent to the next process through the air delivery system.

The machine outer barrel, rotating barrel and the part in contact with the bottle are made of stainless steel AISI304.

Some are welded with high-quality carbon steel, and the surface is rust-proofed and sprayed. The bearing adopts two-way thrust bearing and works without maintenance for a long time.

The fuselage adopts a closed structure to prevent dust intrusion. There are two movable covers on the top of the fuselage for easy maintenance and cleaning.

It is equipped with a mechanism for removing broken bottles and deformed bottles. Normally, there is no need to stop for manual cleaning. If a large number of deformed and abnormally sized bottles cause the drop tank to be blocked, the detection switch inside the machine will issue an alarm signal and stop the machine. The operator can unblock according to the fault indication on the electric control cabinet.

The whole machine adopts SUS304 stainless steel, which complies with the food industry standards.

The equipment design is scientific and reasonable, the structure is exquisite and compact, which saves space compared with other equipment in the same industry

Low energy consumption, the power of the whole machine is not more than 3KW, no compressed air is used, which not only saves energy but also avoids the secondary pollution of the bottle by the unclean air

The breakage rate is low. The breakage rate of the bottle unscramble machine produced by our company can be less than 5 parts in 10,000. If the customer's bottle is not damaged or deformed, it can reach less than 1 in 10,000, which is much higher than 5 per thousand in the same industry.

Can be applied to a variety of bottle types, only need to make simple adjustments to change the bottle type, the operation is simple, does not require professionals.

High production efficiency, compared with peers, the same size and specifications, output increased by 30%.

| No. | Component | Specification | Model | Brand | Remarks |

| 1 | Main turntable motor | 0.5KW/RV50/60 | KAT1Z37-0.5 5KW/4P-0-M1 | YINDA CHINA | 1set |

| 2 | Internal turntable motor | 0.37KW/RV50/60 | KAT1Z37-0.3 7KW/4P-0-M1 | YINDA CHINA | 1set |

| 3 | Brush motor | 40W/7.5 | CHENGGANG CHINA | 2set | |

| 4 | Frequency converter | 0.75 kw | Panasonic Japan | 3set | |

| 5 | PLC | Panasonic Japan | 1set | ||

| 6 | HMI | WEINVIEW CHINA | 1set | ||

| 7 | Low voltage electrical | Schneider France | 6set | ||

| 8 | sensor | SICK | 2set |

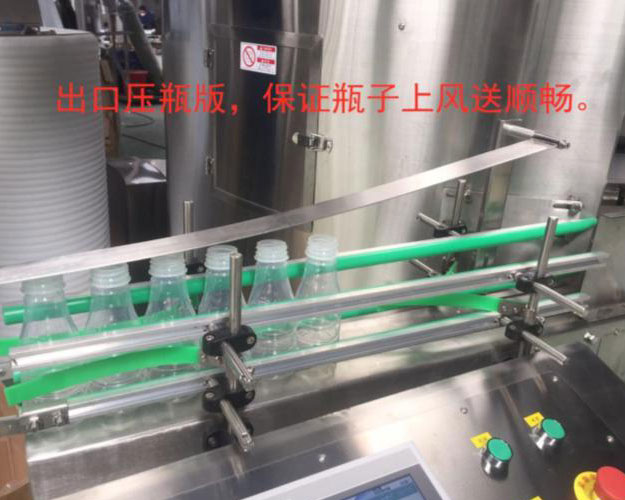

The stainless steel bottle pressing device is used to make the bottle smoother when entering the wind tunnel.

The bottle outlet adopts a movable door, which is connected by a magnet, and the stuck bottle will automatically stop, and the valve will open without squeezing the bottle.

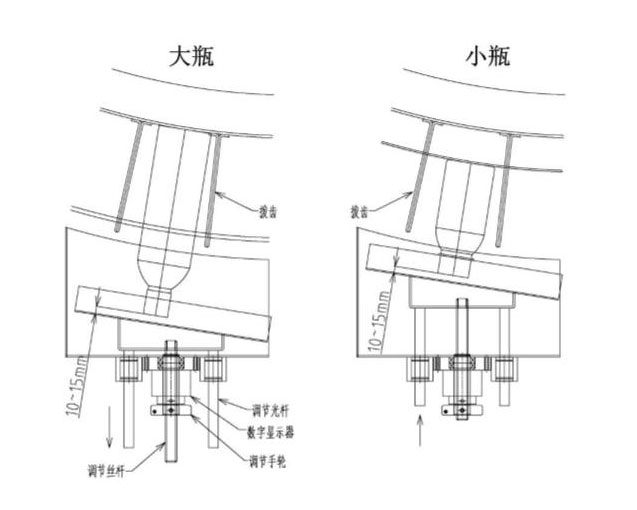

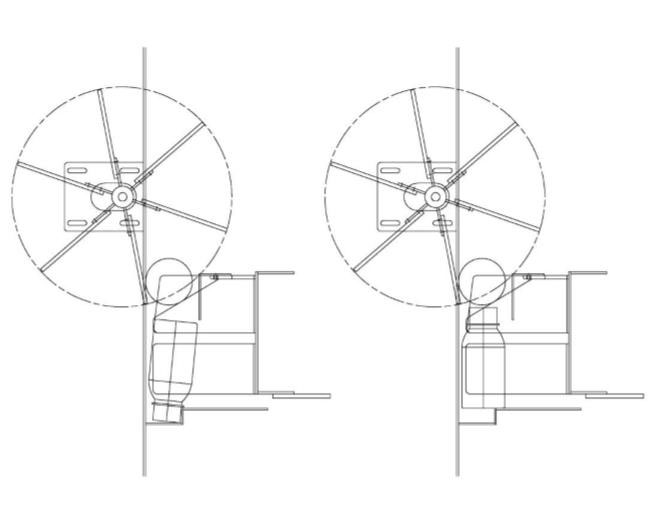

The part that holds the bottom of the bottle can be adjusted to adapt to a variety of bottle types.

The turning part of the bottle uses nylon guide strips to avoid scratches on the bottle.

The digital display of the adjustment hand wheel of the bottle flipping baffle makes the adjustment process more convenient.

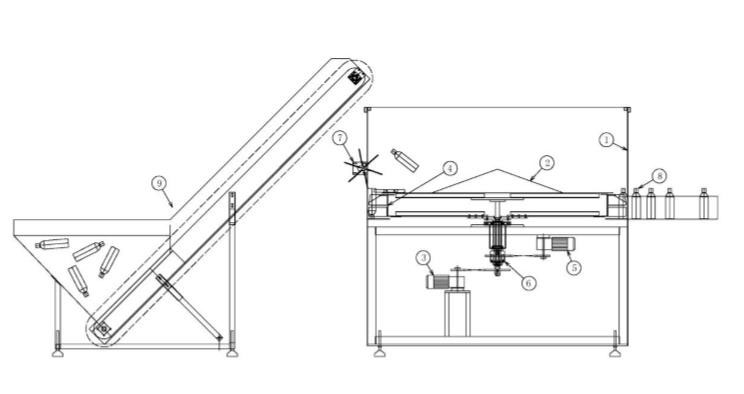

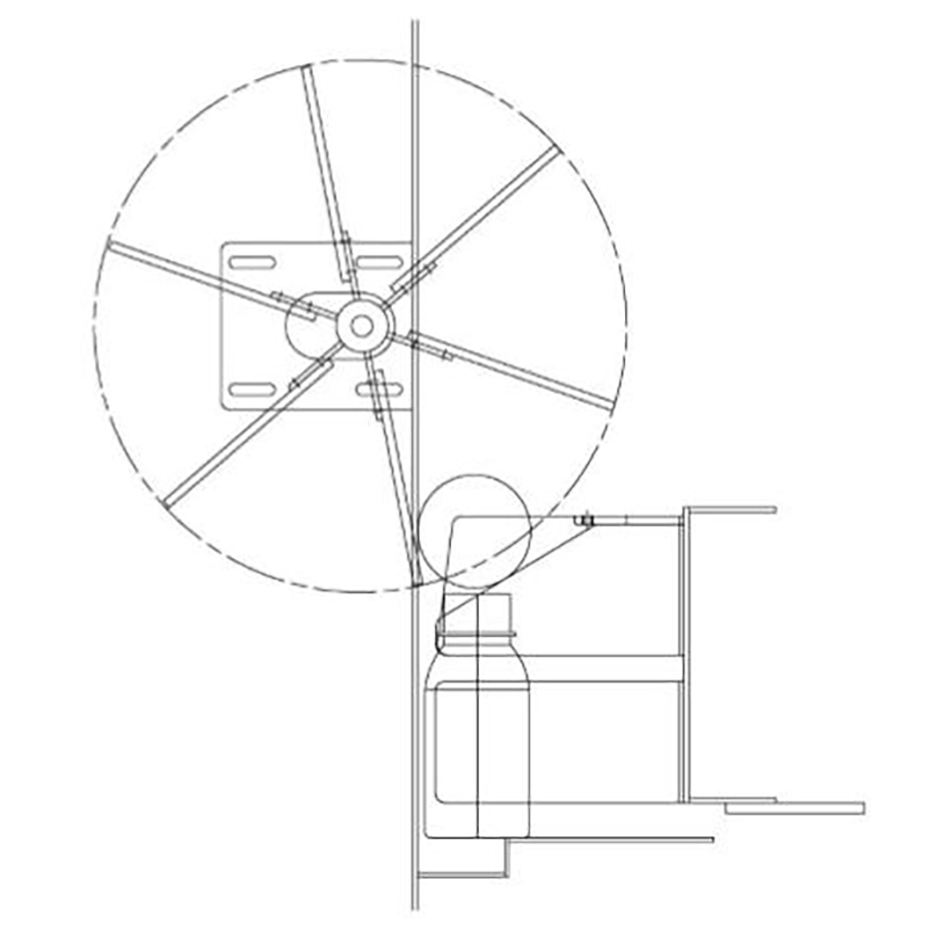

1. Barrel (machine body)

2. Inner turntable

3. Turntable power

4. Outer turntable

5. Outer turntable power

6. Main transmission and power protection device

7. Brush

8. Finished product output

9. Lifting hopper

The barrel body is made of 3mm SUS304 stainless steel plate by round welding, and all the parts inside the machine are used for load bearing.

The top of the inner turntable is made of stainless steel into a cone-shaped top. The function is to distribute the bottles input by the elevator evenly on the circumference, so that the bottles can enter each station of the outer turntable.

Inner turntable power The three-phase motor controlled by the inverter drives the inner turntable to reversely rotate through the chain and the drive shaft. The speed can be adjusted step-less, and starting and stopping can be freely controlled.

The outer turntable is made of stainless steel into each tooth, and then the tooth is welded to the circumferential ring gear according to the parameters of the customer's bottle design, that is, to ensure enough space, and not to enter more than two bottles at the same time.

The three-phase motor controlled by the frequency converter of the outer turntable is driven by the chain and the drive shaft, and the finished bottles are sent to the conveyor line in an orderly manner, and can be automatically controlled by the PLC. stop.

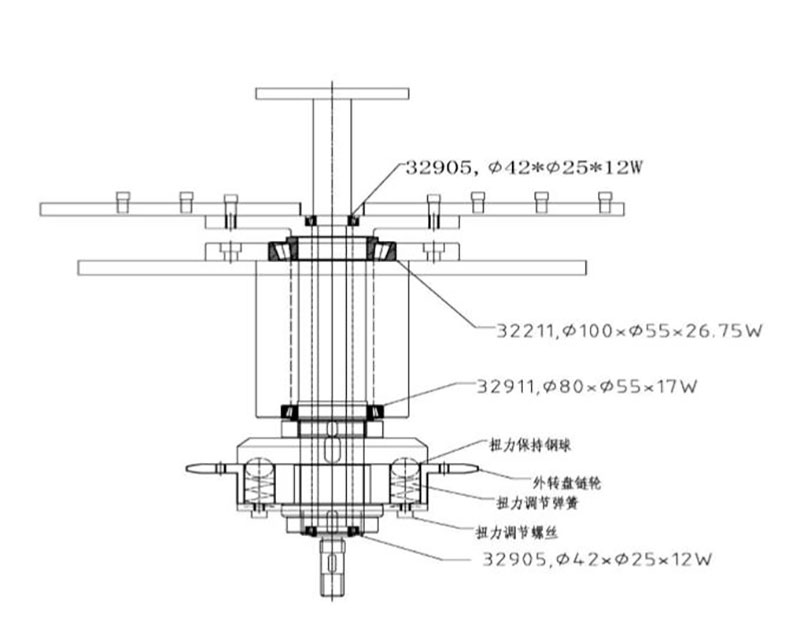

Main transmission and power protection device.

A small motor with adjustable speed drives 6 equal parts of the fixed piece, each piece is equipped with a flexible and friction dial, high-speed counterclockwise rotation, will lie horizontally on the dial or the extra bottle into each slot Clean it up and make sure there is only one bottle per station.

After the bottom of the bottle holder enters the brush area, the lower part of the bottle will have a guide slot opened according to the diameter difference between the mouth and the bottom of the bottle. , The bottle with the mouth facing down, the mouth of the bottle is small, after falling into the guide groove, it is lower than the bottle with the mouth facing upward, the mold cannot stop, the bottom of the bottle falls inward, with the outer ring gear ring Rotate to enter the bottle turning channel, the bottle mouth is pulled out, and push up along the bottle turning ramp to complete the turning. At this point, all the bottles come out with the mouth facing upwards. From this, it can be seen that the bottle or container sorted by the principle of this sorting machine must be not the same size as the upper and lower parts.

Foundation Cream

Make Up Remover

Nail Varnish

Nail Varnish Remover

Shampoo

Conditioner

Liquid Soap

Bath & Shower Gel

Roll On Deodorant

Stick Deodorant

Toothpaste

Fragrance

Perfume

Nail Varnish

Nail Varnish Remover

Shampoo

Conditioner

Hair Gel

Hair Wax

Hair Styling Products

Hair Dye

Tel: 0086-13616137022

Fax: 0086-519-82797687

Email: sales@jpacks.com

Add: No.3 Building 1, Jinbotong, Yangang East Road, Jintan, Changzhou, Jiangsu, China