JLP-200H Automatic Bottle Unscrambler is making up of bottle elevator ,round plate,bottle rejector, bottle-arranging and the electrical cabinet . Put disordered bottles to the bottle elevator, through round plate, conveying belts, bottle arranging parts , then bottles can stand on the belts. This machine is characterized by the compact structure, simple operation principle, mature technique and stable movement.

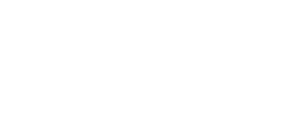

Bottles poured into the rotator plate, with belts conveying to the unscrambling device; bottle standing orderly on the conveyor belts. This machine is of high speed, round and flat bottle both applicable.

No need to change any part when changing the bottle specification. It is with auto rejecter and no-bottle alarm function.

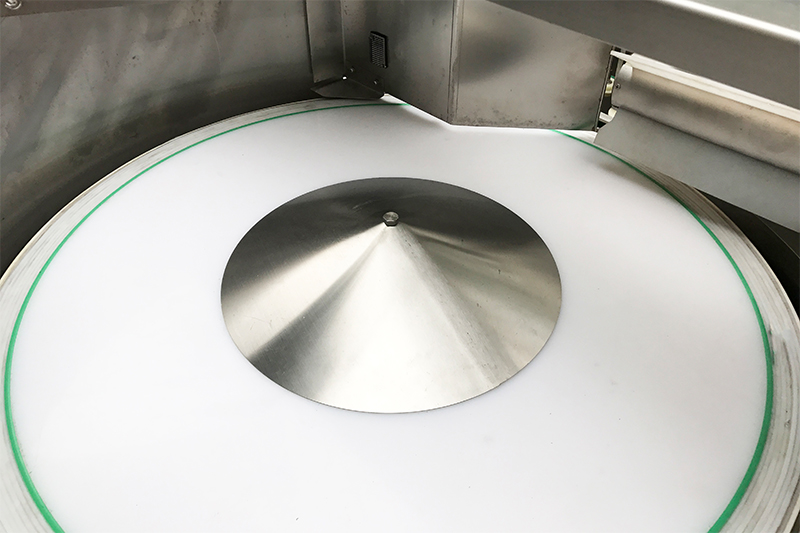

When changing different bottle size, you do not need to change anything, you only need to change the belt in the bottle hopper and adjust the space of the unscrambling structure. And it is applied to 50-1000ml.

Adjust the space of the bottle unscrambling structure according to the bottle size.The electrical components are all imported which ensures its long service time and stability.

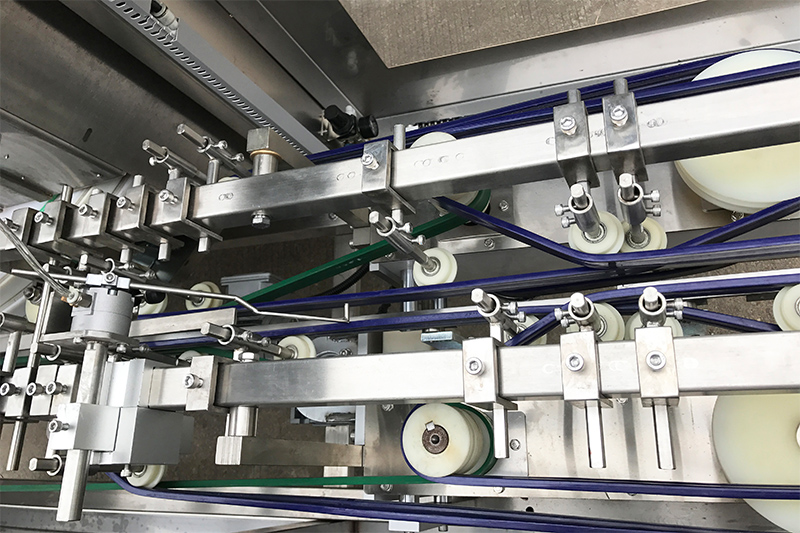

The whole machine is covered with organic glass, you can open all the cover for easy adjustment.

All the organic glass cover is installed with the sensor. The machine only can start when all the organic glass cover are closed,and will stop when any of the door is open.

The connecting belt in the machine are shaped in one time, not easy to broken.

Automatic bottle elevating function, you only need to put the bottles in the bottle elevator, a sensor is installed in the rotary plate, it will automatically elevates the bottles when there is not enough bottle, it will start when the bottles are enough consequently.

Coordination sensor, it will stop bottle unscrambling when there is jam of the other sections of the filling line, it will start again when the jam is cleared. It will have the perfect linkage with the other sections of the filling line.

Unscrambling Speed:≤ 200 bottles/min

Applicable Bottle Diameter:Φ45-90mm

Applicable Bottle Height:80-240mm

Air Pressure:0.5~0.7 MPA

Power Source:~220V、50HZ

Power:1.5KW

Bottle Unscrambler External Dimension:2600mm×1500mm×1500mm(L×W×H)

Weight:About 1250Kg

Frequency converter: France Schneider

Magnetic Switch: France Schneider

Sensor: Japan OPTEX

Power Switch: France Schneider

Cylinder: Japan SMC

PLC: Japan Mitsubishi

Foundation Cream

Make Up Remover

Nail Varnish

Nail Varnish Remover

Shampoo

Conditioner

Liquid Soap

Bath & Shower Gel

Roll On Deodorant

Stick Deodorant

Toothpaste

Fragrance

Perfume

Nail Varnish

Nail Varnish Remover

Shampoo

Conditioner

Hair Gel

Hair Wax

Hair Styling Products

Hair Dye

Tel: 0086-13616137022

Fax: 0086-519-82797687

Email: sales@jpacks.com

Add: No.3 Building 1, Jinbotong, Yangang East Road, Jintan, Changzhou, Jiangsu, China