At the same time, the plane redesigns itself by absorbing advanced technology both at home and abroad. Features: small size, simple transmission mechanism, smooth operation, low noise, high efficiency, wide adjustment range, beautiful appearance and so on. The key driving mechanism of capping machine adopts frequency converter control technology. So that each part of the speed can be precisely controlled, so as to achieve satisfactory use effect.

Buy a ticket For use in flammable and explosive situations, all motors adopt explosion-proof motors and electrical cabinets adopt explosion-proof electrical cabinets.

Vibration disc adopts pneumatic explosion-proof vibration plate, and the positive cover rate reaches 100%.

The machine has a compact structure and is easy to use and maintain.

The body cover is made of 304 stainless steel and meets GMP requirements.

Automatically cover and unscrew the cover to reduce the labor intensity of workers.

The main motor is a gear reduction motor, which is controlled by a Schneider inverter.

Applicable to rotary screw caps and anti-theft caps.

Production capacity: ≤40 0 0 bottles / hour

Applicable bottle diameter: Φ3 5-9 6 mm; height 8 0-2 30 mm (Special specifications can be customized)

Cap specifications: Φ1 2-50 mm; height 1 5-4 0 m m (Special specifications can be customized)

Gas source pressure: 0.5 to 0.7 MPa

Power source: ~ 220 volts, 50 Hz

Power: 2.4 kW

Weight: 650 kg

Dimensions: 2 0 0 0 × 1 0 0 0 × 2 1 0 0 mm (length × width × height)

Frequency converter: Schneider, France

Low-voltage electrical: Schneider, France

Capping motor: China Shengbang Geared Motor

Pneumatic components: AIRTAC, Taiwan, China

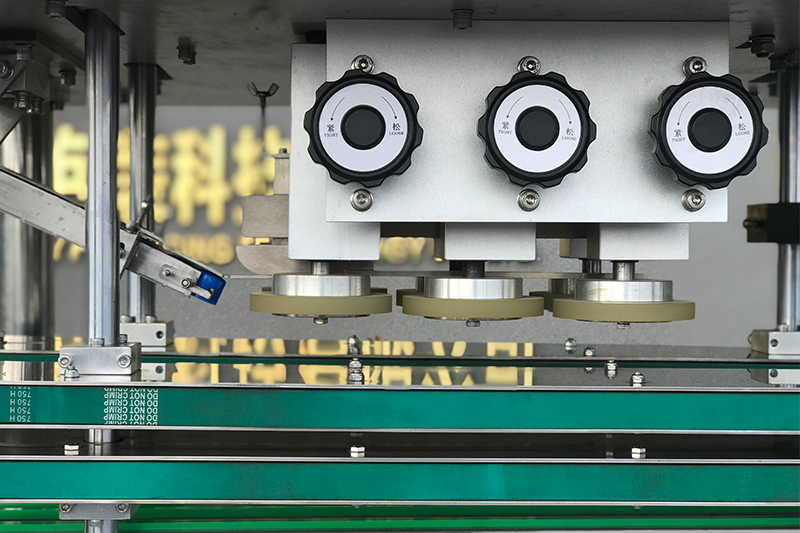

Screw cap elastic device, Chinese and English logo more clear. Easy to operate.

Pneumatic explosion-proof vibrating cap unscramble device.

Explosion-proof electrical cabinet

Explosion-proof motor is used for clamping bottle and capping.

Foundation Cream

Make Up Remover

Nail Varnish

Nail Varnish Remover

Shampoo

Conditioner

Liquid Soap

Bath & Shower Gel

Roll On Deodorant

Stick Deodorant

Toothpaste

Fragrance

Perfume

Nail Varnish

Nail Varnish Remover

Shampoo

Conditioner

Hair Gel

Hair Wax

Hair Styling Products

Hair Dye

Tel: 0086-13616137022

Fax: 0086-519-82797687

Email: sales@jpacks.com

Add: No.3 Building 1, Jinbotong, Yangang East Road, Jintan, Changzhou, Jiangsu, China